Methodology

Firstly, the circuit diagram is drawn using ISIS Proteus software as shown in figure above which include microcontroller PIC18F4431, speed control button, LCD display and optocouplers.

For the coding part, Picbasic Pro compiler is used to generate three-phase PWM signal. This compiler is assisted by MicroCode Studio for the compiling of the coding.

After

the coding is compiled, transfer it into microcontroller in ISIS Proteus

software to generate the PWM signal. The signal is observed using digital

oscilloscope inside the software. The finalized coding is then transferred into

real microcontroller using PicKit2 software.

Hardware

The

real project circuit is divided into four part, microcontroller, LCD,

optocouplers and gate driver connected as shown in figures.

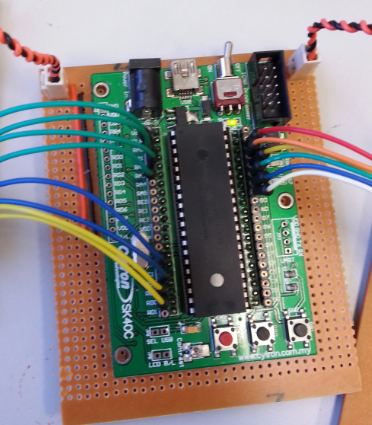

Microcontroller

of PIC18F4431 is used to generate three-phase PWM signal. The PIC18F4431 is

mounted on the SK40C and supply with 5V. The upper part jumper is connected to

the optocoupler circuit whereas the lower part jumper connects to the LCD

screen.

IR2130 is used as the gate driver to turn IGBT

on and off and supplied by 15V. The input of driver from pin 2 until pin 7 is

connected to the output of the optocoupler and the output of driver is then

connected to the input of IGBT circuit.

Three

set of IGBT are used as inverter that converts DC voltages into AC voltages.

The input comes from gate driver circuit and the

three-phase output is connected to the motor.

Result

Figure

at below shows the high side PWM output from the gate driver. A maximum voltage of

about 25V and minimum voltage of 14V is recorded. The mean voltage of 11V is

provided for three-phase high PWM signal.

High side PWM output (gate driver)

High and low side PWM ( gate driver)

The output of PWM signal which the upper signal

(yellow) is the high signal and lower signal (blue) is the low signal. The

deadtime is created when the signal pass through the gate driver circuit. the deadtime is 22 -60 ns.

Single phase IGBT output voltage signal

When the three-phase output

of the IGBT is connected to the motor input, it successfully turns on the motor

and the speed can be adjusted by pressing the increase or decrease button at

microcontroller input part. Some voltages and current are measured during the

motor is running.

PWM

|

Without PWM

| |

Current

|

0.048

|

0.255

|

The table shows that by using PWM technique, the current used can be efficiently reduced which directly means less power is consumed. Whereas the system without PWM, more current is required to run the motor which means it is less efficient since more power is used. Hence, PWM technique is preferred compare to system without PWM.

hi can you email me the source code ia am working on a similar project

ReplyDeletehi am shankar from chennai and i am also trying this project. please can you send or give links to source code for this project. my email : lambdashankar@gmail.com

ReplyDeleteI am also working on similar projects. Would you like to share your thoughts , circuits and source code please

ReplyDeleteI am also working on similar projects. Would you like to share your thoughts , circuits and source code please. shehab507@gmail.com

ReplyDeleteI am also working on similar projects. Would you like to share your thoughts , circuits and source code please. boutiche.amine@grtg.dz

DeleteI am also working on similar projects. Would you like to share your thoughts , circuits and source code please. boutiche.amine@grtg.dz

ReplyDeleteCan I get the source code and files for the 3 phase motor control for my project..thanks

ReplyDeleteEmmanuelwizardd@gmail.com

ReplyDelete